Free Consultation

Wanna chat? Tap to call or text

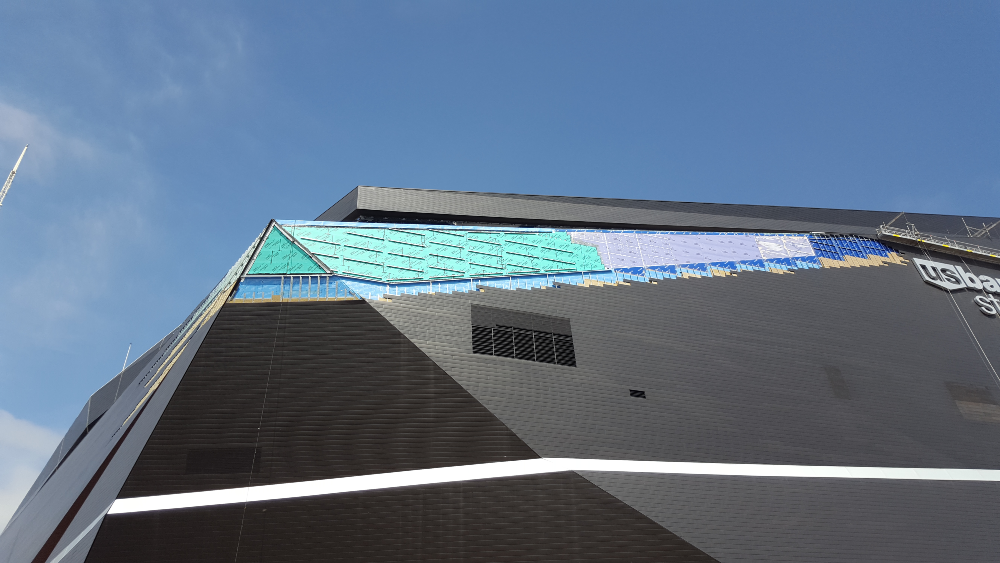

A building envelope is the physical separation between the interior and exterior environments. This barrier separates the inside from the outside, protecting the occupants from any external weather conditions such as rain, snow, and hot or cold air. It also helps maintain an appropriate temperature within the building during summer and winter while controlling energy consumption.

The building envelope can include:

A standard commercial building envelope comprises components that work together to form an effective barrier. From cladding that is visible to the outside world to more intricate layers that manage moisture, temperature, and air, each component is a critical piece to creating an effective building envelope.

The air barrier layer plays a crucial role in maintaining indoor air pressure and safeguarding the indoor space from external pollutants. This layer forms a reliable seal that retains heated indoor air during cold winters and offers resistance against wind-driven moisture in humid climates, thus preventing it from permeating the walls.

There are several materials available for constructing the air barrier layer, including rigid foam boards, spray foam insulation, caulking, and masonry treatments. It is of utmost importance to ensure the proper installation of all components of the air barrier system, particularly around windows, doors, and other openings, while also considering the specific climate requirements of the building. By incorporating an effective air barrier into the building envelope, energy costs can be reduced, occupant comfort can be enhanced, and the entry of indoor contaminants can be prevented, thereby mitigating potential health hazards.

The vapor barrier layer helps prevent moisture from entering and condensing within the walls.

Various materials, like polyethylene plastic sheeting or paints, have the potential to serve as vapor barriers; however, it is crucial to carefully choose the most suitable option for your specific needs. Factors such as permeability, placement within the envelope layers, and local climate conditions must all be taken into account during the selection process. When properly installed, a vapor barrier control layer plays a key role in maintaining a healthy and comfortable living environment, as well as preventing expensive repairs in the future.

Various materials, like polyethylene plastic sheeting or paints, have the potential to serve as vapor barriers; however, it is crucial to carefully choose the most suitable option for your specific needs. Factors such as permeability, placement within the envelope layers, and local climate conditions must all be taken into account during the selection process. When properly installed, a vapor barrier control layer plays a key role in maintaining a healthy and comfortable living environment, as well as preventing expensive repairs in the future.

The thermal barrier control layer within a building envelope is responsible for regulating the temperature differential between the interior and exterior spaces. This is crucial for ensuring comfort and protecting the structure from issues like mold growth, condensation, and structural damage caused by extreme temperatures.

Materials such as rigid foam insulation, spray foam, and specialized insulation types can be utilized as thermal barriers. Proper placement of the insulation layer in relation to other envelope components is essential for optimal performance. It is also important to consider local climate requirements when selecting the type and thickness of insulation material. When implemented correctly, a thermal barrier control layer helps to create a healthy and comfortable indoor environment while preventing costly repairs in the long term.

The water barrier control layer in a building envelope serves the purpose of preventing water from infiltrating the walls and other components of the structure. The consequences of water infiltration can be severe, ranging from the growth of mold to the deterioration of the building's integrity and increased energy expenses due to insulation requirements.

Depending on the specific application, specialized membranes, and other materials can be utilized as water control layers. However, it is important to note that different materials possess varying levels of permeability.

For all layers, local climate conditions must be taken into account and considered when determining the type and thickness of material to be used. The building envelope should not only withstand local weather conditions but also leverage those conditions for better performance and durability.

Each layer works in harmony with the other layers and together they create an effective building envelope. By employing proper design and construction techniques, you can guarantee that your walls are capable of withstanding the elements and creating an effective barrier between the inside and outside of the structure.

Testing a building envelope is the process of testing the physical separator between the interior and exterior of a building to determine if there are any air, water, or thermal leaks within the structure. This process is completed by a third-party expert who works with the architect, building owner, or general contractor.

After testing is completed, the design/build team can review the test reports for evidence of air and moisture infiltration and may even be able to see visible traces of water leakage. It is not uncommon for wall systems to fail testing, but that is not necessarily a negative thing.

Through the use of quantitative and visual analysis, it becomes possible to determine the precise locations of failure and identify any instances of improper product application or flaws in the design itself. Armed with this knowledge, the design/build team can then proceed to make necessary adjustments to their designs or material selection. By conducting such comprehensive testing in advance, the potential for expensive damage and rework in the field can be mitigated.

Factor is a third-party expert and one of very few professionals in the United States that conduct non-destructive testing of building envelopes. We test curtain walls, window systems, and glass and glazing systems according to the American Section of the International Association for Testing Materials (ASTM) and the Fenestration & Glazing Industry Alliance (formerly AAMA) standards. Schedule your consultation today!